This is a long post but its a long story, starting in 2010 when the EPA prematurely mandated the implementation of DEF systems on diesel motor vehicles. This is old, proven technology that works fine in stationary facilities such as factories and power plants, but was simply not ready for the mobile environment when forced on the driving public. So…..

A lot of confusion comes from changes in systems over the years (2007, 2010, 2016 etc) and yes, different chassis manufacturers. Spartan uses Shaw DEF heads as does Tiffin on the Powerglide chassis. But both Newmar and Tiffin also offer many coach models on Freightliner chassis. FL‘s supplier (TE Connectivity for mine) seems to have solved the problem with their DEF “Headers” (FL‘s term - everyone else says DEF head) while those using Shaw lagged a couple years behind causing all kinds of chaos and troubles. They claim they’ve finally got it right with Gen 7 or 8 - we’ll see.

The big problems are old DEF which is out of spec for the quality sensor (2016 and later) and high temperature which causes both a higher concentration of ammonia (damaging to all systems) and precipitation of salts which cause the float to hang up on pre-2016 systems as noted in the following TSB: (

https://static.nhtsa.gov/odi/tsbs/2013/MC-10142383-9999.pdf).

High temps occur environmentally which is why there is a scale for DEF shelf life from over a year at around 60*f to 90 days at over 100*, but also can be due to a stuck tank heater valve. These valves fail in the open position heating your DEF to engine temp levels which of course destroys the DEF and subsequently the header. Smart design, huh? An easy fix here is to install a valve in the tank heater input line and shut it off and only open it if you are going to be driving in sub-freezing temps. They say DEF starts turning to slush at about 12* so that gives most of us a lot leeway.

Last Fall the EPA finally responded, but with a weak solution to the problem, allowing engine to manufacturers to upload a software fix to work around the problem because of an extreme shortage (using Covid as the Great Excuse) of parts but this did nothing for the stranded motorist and the restrictions placed on getting it done are just as extreme as the problem. So far I’ve read of NO ONE who has found this solution satisfactory. And of course the real problem is dependance on off-shore manufacturing, not Covid.

Diesel Exhaust Fluid (DEF) Updates

www.epa.gov

Another solution mentioned above is the DEF sensor simulator (DSS). This is a much more effective work around and puts control in the vehicle owners hands, but will only work on 2016 and later emissions systems and requires some skills that are slightly above the basic level to build. The link noted above provides good comprehensive instructions for acquiring parts, building, programming, installing and testing it, but it isn’t just plug and play. But it does work and is an excellent item for coaches with 2016 and later emissions systems and my recommendation is to buld one and keep it with your spares in case you need it, and not waiting until you need it to pursue this solution.

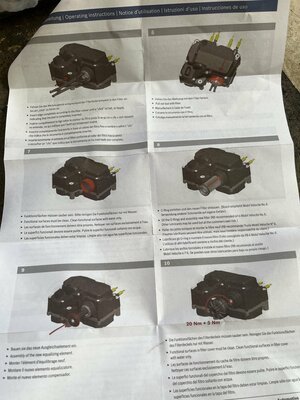

For pre-2016 system owners, the following link is IMPORTANT and even if you can’t do this fix yourself, a shop can IF they are aware if it. This is also why they say “keep your DEF tank full” but why its only applicable to pre-2016 systems. One thing you can try if you are getting the dreaded “false low DEF” codes and facing de-rating, is to flush the tank a couple times with water (preferably distilled or very clean filtered) and then refill with new DEF. This has worked for some and avoided actual mechanical work on the vehicle. Also the image in the TSB also shows the electrical connection to the header which you’ll note is why the DSS will not help with this type of system (older analog vs newer digital parts)

https://static.nhtsa.gov/odi/tsbs/2013/MC-10142383-9999.pdf

My coach is a 2016 but the chassis was built in 2015 and made it under the wire before the 2016 emissions came in to effect - another source of confusion. Pre-2106 systems just have level and temp sensors, and the sensor unit (DEF head(er)) is actually serviceable in many instances of failure. Post 2016 has level, temp, amd quality sensors, they are solid state, and the electronics in the sensor head are much more suaeptible to failure for a variety of reasons. These post-2016 sensors are also done once they fail, and failures were so high initially that a significant shortage occurred leading to waiting lists, stranded motorists, and rigs stuck at shops waiting for parts.

Meanwhile one of the most significant problems are misinforation and a lack of education for the owner/operator. Dealers don’t want to talk about it, the EPA took forever to even come up with a lame attempt to help that really doesn’t, and shops love the easy money and job security. So consumers are left to figure this put on their own.

I have read many accounts of people spending $2-3k or more for work that is actually covered by the emissions warranty. I’ve sent a handful back for a refund and all have collected some or all of their money, but imagine the countless others who were taken on this. My theory is that shops do this for two reasons: 1) it’s easier to swipe a customer’s card than file paperwork and wait for payment from the manufacturer, and 2) they can charge the consumer A LOT more for the same work than the manufacturers will pay. Yes, laziness and greed. Go figure. Meanwhile dealers pretend the problem doesn't exist because they want to sell coaches, and because a lot of them don’t understand the vehicles they are selling.

So the moral or this story is to learn your vehicle, understand the emissions system for your model and year, know your warranty, and don’t take an unsatisfactory answer at face value. Get a code reader, preferably one with some basic emissions commands, and verify everything before handing over big bucks for repairs.

The article below gives a good explanation of DEF and also reminded me of another debate: pump (bulk) versus packaged DEF. Since the coach DEF systems have proven fragile, I only use packaged DEF with a decipherable date code for my coach, and this is my recommendation for anyone with a diesel RV, regardless of the manufacturer. My 2017 Ford F250 seems to be much more robust so it can use pump DEF. I also don’t depend on it as my domicile many miles from home.

en.wikipedia.org

A parting comment, then I’ll stop editing and updating all this: none of the DEF components or issues have anything to do with your DFP and regens (passive, active, or parked/forced) as DEF is introduced to the SCR AFTER the DPF. I’ve both experienced and read of instances where a shop tech will reccomend and/or perform a forced regen when faced with DEF head(er) codes, and then charge for it. Regens wont help with DEF issues, and DEF issues wont cause DPF problems so it’s important to separate the two when dealing with emissions related fault codes.