JBeasty

RVF Regular

- Joined

- Aug 15, 2021

- Messages

- 9

- Location

- Northern California

- RV Year

- 2021

- RV Make

- Gulf Stream

- RV Model

- Envision SVT21QBS

- RV Length

- 22' 6"

- Fulltimer

- No

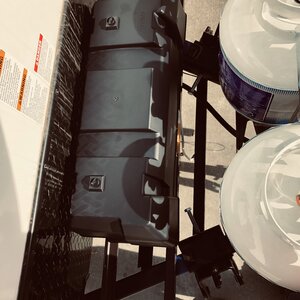

I'm attempting to set up dual batteries in my trailer a-frame area with limited space. My Husky WDH lift brackets occupy the same space as the current battery hold area. I could gain enough space if I shortened the bolts on the inside of the brackets, and then moved the brackets outward by putting a spacer on the outside of the a-frame (between the brackets and a-frame, held in place with bolts). Essentially, I'd be moving the brackets over so they are flush with the inside of the a-frame, and the bolt on the inside would be shortened enough to clear the battery - if that makes sense. Has anyone done this? See any problems with altering the WDH, as long as the lift chain is centered on the bracket? Any input would be helpful.