Chuggs

RVF Supporter

- Joined

- Nov 3, 2019

- Messages

- 633

- RV Year

- 2016

- RV Make

- Newmar

- RV Model

- Ventana 4037

- RV Length

- 40’

- TOW/TOAD

- Jeep JKU

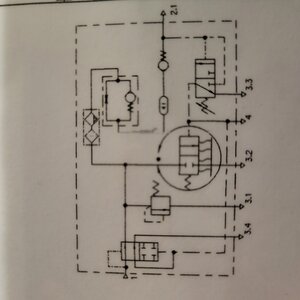

I read your thread and you were on the right track. I don't know the model you have...but they generally work the same way. To purge, there needs to be air. With the compressor not running or running but unloaded...[ie at cut-out pressure and not bled down to cut-in pressure]. Once the purge has happened at cut-out...it should exhaust all of the air held in the cartridge body and purge tank either external or internal. No more air should be available. If the purge valve leaks air after about 30 seconds...the air could be backing up thru the discharge check valve, most likely, as you eluded to. (inside the port that the line to your wet tank connection is screwed into,,, Port 2.1 on a lot of dryers). The check valve and likely the system hasn't bled down to cut-in pressure yet...thus holding the purge valve open. But...there are other locations that might need attention. Your governors interntal o-rings or the inlet/exhaust seal could be fouled. The air could seep from the turbo cutout valve if it's stuck, exhaust port on governor. So, at some point, you kinda have fo verify where on the system the air is actually escaping. It's helpful to know...does the Purge valve start leaking when your tanks are empty, and the compressor first starts running and you has not reached cut-out pressure? Or does it happen only after cut-out but before cut-in? Etc...

It's a simple but complex little device.

I had one leaking at the purge valve on startup. Purge valve for sure... yeah, no...I took the purge valve out, examined it, and reinstalled it with new lube. Twice to no avail. Still lets air out. I put a new air dryer on the coach, because we didnt have time to kill. Now, at home, I cleaned and lubed the outlet check valve, governor, turbo cutout, purge valve...and tested it on the bench...adjusted governor cutout pressure...all works good on that unit again. You won't believe how gummed up these valves can get over time. Having a heavy duty set of split ring pliers, cleaning materials, lubricant...will generally fix the problem unless you find a bad component...o-ring, piston body or valve seat, spring, etc... but they sell little kits for all of these components. Wabco has blueprints of the different dryers they make. If you can read a pnuematic circuit diagram...it really helps understand the operation and pathways.

It's a simple but complex little device.

I had one leaking at the purge valve on startup. Purge valve for sure... yeah, no...I took the purge valve out, examined it, and reinstalled it with new lube. Twice to no avail. Still lets air out. I put a new air dryer on the coach, because we didnt have time to kill. Now, at home, I cleaned and lubed the outlet check valve, governor, turbo cutout, purge valve...and tested it on the bench...adjusted governor cutout pressure...all works good on that unit again. You won't believe how gummed up these valves can get over time. Having a heavy duty set of split ring pliers, cleaning materials, lubricant...will generally fix the problem unless you find a bad component...o-ring, piston body or valve seat, spring, etc... but they sell little kits for all of these components. Wabco has blueprints of the different dryers they make. If you can read a pnuematic circuit diagram...it really helps understand the operation and pathways.