I toured the factory today with Rick from Sales, and also had a great discussion with Toby, co-founder. Here are some pictures. The video at the start of this thread does a great job of touring the facility, consider these pictures an update on specific assembly bays with ongoing activity. My observations are not conclusive, just what I observed on the day.

A quick caveat ... I've followed the Lightship journey since inception, so my observations on final product are relative to my reasonably informed baseline.

Picture 1 - Stack of pre-fabricated floorboards

Picture 2 - Non drive axle

Picture 3 - Pre-fabricated chassis

Picture 4 -Trek-Drive unit

Picture 5 - Assembly bay 1 - wiring harnesses, drive unit install, front/rear axle install, pre-install canopy lifting mounts

Picture 6 - Assembly bay 2 - water tank install, plumbing, tongue box pre-wire

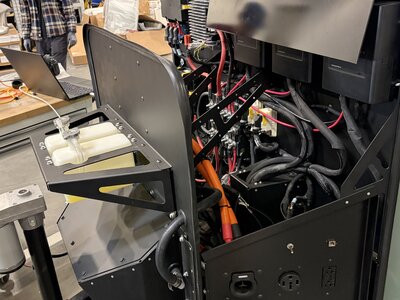

Picture 7 - Assembly bay 2 - battery install, wiring

Picture 8 - Assembly bay 2 - close up proprietary lightship hitch and force sensors

Picture 9 - Assembly bay 3 - canopy lifting units, note the new "tape measure" style dust protectors

Picture 10 - Assembly bay 3 - floor install, canopy lifter install and calibration, tongue box final

Picture 11 - Assembly bay 3 - tub panel installation

Picture 12 - Assembly bay 3 - tub panel staging (just in time)

Picture 13 - Assembly bay 3 - tub internals, drawers, panels etc.

Picture 14 - Canopy bay - internal wiring

Picture 15 - Lightship internal unit (1 of 2), interior in Canyon Rim

Picture 16 - Lightship internal unit (1 of 2), *NEW* table (now two legs, and motorized), previously single pole mount and manual action

Picture 17 - Lightship internal unit (1 of 2), tongue box - almost complete

Picture 18 - Grey/Black water outlets, updated design, no longer a single fixed pipe, allows for multiple pipes to be attached based on requirement

Other notes:

According to Toby and Rory (CFO), orders are going really well. If I remember correctly from the brief discussions I had with them, new orders are now projected for fulfillment late Summer 2026. Having previously run manufacturing sites, there's a way to go for them to commence volume ramp, but you can see the pieces coming together and they are learning quickly.

Overall I was significantly impressed with the material choices at every stage, the quality of workmanship in all the sub-components, particularly the chassis and wiring harnesses were very impressive, and the overall focus on getting it right really came through. The videos posted at the start of this thread really did the facility justice, and it's interesting to see the facility a few-weeks later in the early stages of production flow.