I was confused initially as to what involvement the Federal Communications Commission might have over the service center then realized that's probably a different FCC.

I now better understand why in middle school English class we proof read each other's work before turning it in, that's essentially what the second dealer is doing for the first, only you get to pay for both.

I wouldn't think an exhaust leak after the turbine would be super loud beyond a whistle. I would imagine a large boost leak from a fitting the size required to feed the air compressor to be extremely loud, especially when more power was being called for.

The less than competent service place really does need to make this right and figure out internally what changes are required to ensure this poor level of service is a thing of the past. While the time and money are of less concern to you, it's a function of principle. If they're not set straight it only empowers them to perpetuate the kind of service and attitude you received to everyone else in need of getting work done correctly the first time.

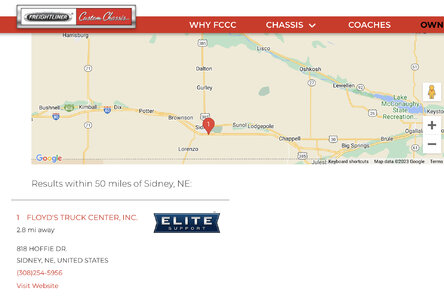

Yes, its FCCC - Freightliner Custom Chassis Corp.

The exhaust leak that was making all the noise when I took it to Floyds initially was before the turbo - right at the head - the manifold warped enough to break bolts. The exhaust leak noted in the write up from Truck Centers that was at the turbo outlet flange was a new development resulting from incorrect reassembly. Floyds had to R&R the turbo to change the manifold.

We listened for obvious intake system leaks several times over a couple days as this situation evolved, (by putting it in gear with brakes applied and putting it under load), and could never discern anything out of the ordinary although it did seem to sound different when driving right next to k-rail and that could have been an intake system leak.

The exhaust manifold leak was clearly a new development when I started the engine the next morning after spending the night at Cabela‘s in Sidney - my guess being that it got worse when everything had cooled because we did not hear it at all the day before. And there was no way anyone could miss it - it was loud from the driver’s seat.

The other startling discovery was the radiator hose rubbing on the frame after reassembly. This again was a new condition resulting from incorrect reassembly and a ticking time bomb. I can easily imagine it leaving us stranded again weeks or even months later, with no recourse and checking everything Floyds did, including the radiator and CAC R&R, was one of the chief reasons for driving directly to another shop under different ownership after leaving Floyds. One shouldn’t have to do this but I had a bad feeling about the reassembly work, and obviously for good reason.

And believe me I’m not going to ignore this and having one Freightliner Elite service center document and fix another’s mistakes will be a point that will be very difficult to ignore or dispute. Especially if I involve Freightliner which I most likely will. My point was that while this didn’t impact me all that much (other than missing my week at the Mothership), it would be devastating to some and as such must be addressed and corrected.