From the thread "It is time...for new house batteries" - introducing the new house batteries! This article and discussion will likely evolve, I'll do my best to tell the story with as much detail as I can remember. It has been quite the week and a ton of information. The overall theme I want to share from my experience is "you don't know...what you don't know!" I could not be more thrilled with the outcome and how things transpired and my absolute kudos to Solar Energy Systems (SES) in Nappanee, IN (2 miles from Newmar) that took on this job on short notice and were beyond accommodating. They do not know (prior to the job) of this site or my relation to it, there is no sponsorship or affiliation - I paid cold hard debt for this! One item of note, apparently this year there is a 30% off solar (or batteries) tax break which I'll be asking my accountant about so hopefully I can take advantage of a write-off for this tiny investment (sarcasm). SES is one of the major Victron "hubs" in the US as they are a distribution center, training center, installation, and repair center (IIRC). Moral is, they know Victron!

Solar Energy Systems - Solar Installers - Nappanee, IN

Solar Energy Systems is a leading solar installation company in Nappanee, Indiana, providing solar energy solutions for residential, commercial, farm, and RV's.

sesindiana.com

sesindiana.com

Several weeks ago, when I created the above referenced post, I emailed Battleborn as I chatted with them a year ago but nothing transpired. I emailed them I was ready to move forward and gave my desires - I never got a response.

As I was at the Newmar Hoots rally in Hilton Head, I think was the time, I had an idea. I'm heading to Newmar for service and I really need house batteries as I was having a problem with my APC UPS (battery backup) and electrical weirdness when switching between shore power and batteries. It was time and I really didn't want to do this job. I decided to reach out to Solar Energy Systems, I have no idea why that thought came up! I got an immediate response and started figuring out a plan.

My initial plan was to keep my Magnum 2812 inverter and I already have solar, a Victron solar setup with charge controller, BMV-712, Venus GX, etc. I just need batteries. Brian B is the one I worked with (there are three Brians there) and he steered me away from an external BMS as he said if it detects something wrong in the batteries it will shut the system down. Now before I get too far into this, I had a lot of discussions and I very well have remembered something wrong so I'll do my best. But I understood and decided to go with their Elevation batteries, 8 x 120's but the number was in flux as it all depended how things fit. The alternate option were their elevation 100ah batteries. In the end I learned the Elevation batteries are ones they make, and they are very good. I wanted the design to be expandable, i.e. have slots on the bus to add batteries with ease should I want to add more later.

They scheduled me in for Mon-Wed of the week after my Newmar service. While going to Newmar I just didn't think I had that much to do and shouldn't be there the entire week which was allotted. I told SES that I may be done Wednesday so they booked manpower to be available for Thursday and Friday for the job and in the end that is what happened, Newmar did great and finished me Wednesday so Wednesday night I drove over to SES as they have 5 RV sites with water and electricity but water, like at Newmar, was shutoff for the winter. SES has a brand new facility, not sure when completed, but it's huge.

I arrived Thursday morning for the 0700 show time and met with Brian B to discuss the plan. In walking their showroom I told him how much I really liked Victron and really wanted to go with Victron - long story short I blew up the plan and we are now going all Victron as I saw how compact the Victron 330ah batteries were, but priced at around $3300ea, ouch! I want to do this right and enjoy it and be proud of it. On the way to Newmar I asked Brian about a dual inverter setup and it was an additional $6K because they need to redo the wiring to support the loads to run 2 x A/C's as Newmar's wiring is not sufficient. I declined. Right up until Thursday morning when I decided to go all out and do it right as Brian even said, you'll be back in a year or two to ask us to do this and it will cost more to do it then vs. now. The Victron batteries require an external BMS (as listed below) and I'm fine with that, it's the right way to do Victron! Once I told him of my love for Victron he showed me his electrical room with a wall full of Victron that is running their facility as obviously it's fully solar powered and supported - very cool!

I wanted to see how much the Victron 330ah batteries weighed and noticed what other vendors were selling them for - $2200! Wow, that's an amazing price compared to the Battleborn GC3's I was considering which are 270ah batteries. I emailed Brian of the price difference in that I wanted to give him my business but I wasn't thrilled with throwing away $1100 per battery. I asked if he could match the price. He contacted his rep, the pricing had just dropped, he matched the price. Hallelujah! The plan is now set for 4 x Victron 330ah batteries, dual Victron Multiplus inverters, Smart BMS, Cerbo GX, vent fans controlled by the Cerbo GX to ventilate the battery bay, AGS module that allows Victron to control the generator with far more control the Magnum even allowed. I learned from Brian that mixing vendors is not ideal as things don't work well, I won't get into the specifics of that discussion.

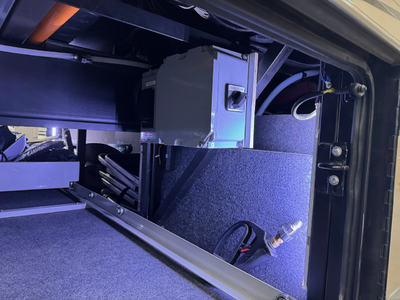

Day 1 was mainly demolition, removing all the old stuff out. My solar charger setup was all in the pass through bay on the wall and I wanted it all cleaned out and properly installed into the new sealed battery bay. They put temp batteries and inverter in place so I could stay in the coach in the evenings, so that was nice.

Day 2 was a little disappointing as at the end of day 1 they hyped the plan for day 2, then the morning of day 2 the same, and the day ran long so I expected major cool stuff to see but was let down. They simply paneled the bay using what they call FRP which is a white coated stiff board and also used spray foam behind the boards and also sealed the edges, etc.

I didn't want a white bay so I picked up carpet the week prior from Newmar parts and wanted the bay to be like the rest of the coach. I also purchased headliner 3M adhesive from Amazon and a roller to adhere and install the carpet which they did an amazing job on. The battery bay got a gasket added and I also removed the two bumpers Newmar installed on the door to help it vent for lead-acid batteries. I'm still working on the gasket situation and ordered a different adhesive backed gasket from uni-grip.com which is Newmar's supplier for bay gaskets but what's installed seems to be working well.

The job completed Thursday noon, a day later than planned but I threw changes at them and it was a major job. The job included changing out the wires from the transfer switch all the way to the half bath breaker panel which goes through the dual inverters using 6 gauge (if I remember correctly) wires otherwise what Newmar installs would melt from extended air conditioner use. There is a switch installed in the pass through bay, pictured below, which allows me to control the path of electricity from the default, threw the inverters, or there is an inverter failure, I can direct it to the stock Newmar way which is transfer switch to breaker panel.

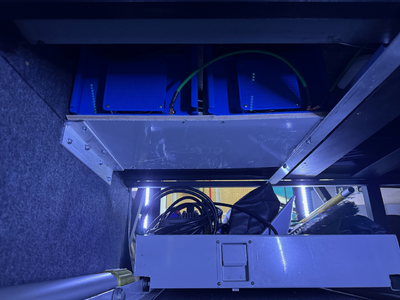

I wanted the setup built for expansion so prior to the batteries going in Tuesday morning we looked at a 4 battery plan and 8 battery plan as I may add 4 more in a year or two. First I want to see how 1320ah works and is likely more than adequate but who doesn't have get'more'battery'itis? With that I decided, just like the initial plan, to ensure the system was plumbed for expansion so I had them add an additional Lynx distributor which is on the left wall which is where 4 more batteries will connect.

The victron setup is beyond amazing in that it is such a great design by using Lynx distributors instead of bus bars to connect batteries, Smart BMS, loads to coach, solar, etc. all fused and monitored by the Cerbo GX unit which has a display in the coach where the former Magnum ARC-50 was located. They had to run both a USB and HDMI cable up to the box for that display and control head as well.

Back to the theme of "you don't know what you don't know" became very evident throughout as SES has electrical engineers that design these setups ensuring proper wiring and safety and of course functionality. On top of that SES is also a member of my Victron Remote Management (VRM) portal and as I've done the past few days I've had questions and they reviewed items in this hefty setup. It has been quite a learning experience to date. While the price may seem steep to many, it's justified based on what is installed and the amount of labor that went into it. When you look at the cost of these components, batteries alone, then add 5-1/2 days labor with two people on the job non stop, and the engineers, post job training, and tech support on call, it's a job done right. I was also informed that SES does some of Newmar's Lithionics work and has also briefed and trained them on how they do wiring so Newmar won't go "we didn't do that, we're not touching it" so they are on board with what SES is doing to Newmar (and other) coaches that they may see.

Towards the end of the job I had an idea to box in the batteries with FRP and carpet to make it look clean and also decided to add the heating pads as LiFePO4's won't charge below 32F. What I've been surprised with though is that batteries put off heat just by doing their battery thing and even in freezing nightly temps they've been around 60-70F. We have a temp sensor in the battery bay that shows me the temps on the VRM portal and can also alert me based on alarm rules, and my wet bay temp sensor I installed from the prior setup is also integrated which is nice. The temp sensor also controls the battery bay ventilation fans so as heat rises in the summer it will ventilate the bay automatically.

So we (they) boxed in the batteries with adhesive heating pads installed and also put two vent holes on the right side per my direction which came out nice. I decided to go with a dual inverter setup which allows the coach to remain energized to 50A at all times. There is nothing in the coach I cannot run on batteries as if it was on 50A shore power. Another amazing feature of these Victron Multiplus 3K 120V inverters is a feature called PowerAssist. If I'm connected to a shore power source of at least 7.5A then the system will augment shore power with battery power to allow the coach to add 25A to whatever is coming in. For example, if I'm on a 30A shore power connection, the coach will still operate at 50A as it will supplement 20A from the batteries. Way cool!

One nice feature I noticed on the Victron Multiplus inverters is they also serve as a UPS such as for computer equipment. As I bring my PC tower along I to date have had an APC BACK-UPS battery backup system I've had to use not only for surge protection but to keep the computer running when there is a power transfer such as from shore to battery. Magnum never handled this well and Victron says their inverters switch over so fast that computers will remain running. Sure enough I tested this out and it worked perfectly. Computer on, shore power, then went out and turned the breaker off and the computer was fine. No APC inline, so that is now out!

The AGS and control of it is amazing through tons of "conditions" you can set on the Cerbo GX unit. Quiet hours, SOC and voltage conditions but also conditions while in quiet hours such as if you get below a certain SOC even within quiet hours the GEN can come on.

LiFePO4's, or Victron at least, can run down to 10.0 volts before requiring a shutdown. The BMS manages everything from cell balancing but also temp and voltage limits which is nice. It will also alert as needed for any fuse issues, cell issues, etc. so you are aware of anything and everything as needed in this system.

The control from VRM (web portal) is amazing as well, far more than what I had in my previous setup. I can control the inverters such as I did today to allow a discharge cycle which you should do with LiFePO4's at some period of time, which I'm still learning as I've heard monthly and also semi-annually. Using VRM I put the inverters into "inverter only" mode instead of inverter and charger and this allowed the batteries to take on the full loads and with OASIS on AC I for heat, it's pulling 30A's when OASIS runs. I can also control the GEN remotely so after I did the above I wanted to exercise the GEN so I put it on a timed run for 30 minutes to take over the charging a bit after the demands I put on the batteries.

A Li-BIM is installed that manages the charge flow while driving. I asked about any concerns of the Alternator as discussed on this site and he said he's never heard of a problem and that is what the Li-BIM is there for. The one downside of the Li-BIM which charges based on a timer, I believe, is you can arrive at your campground less than 100% SOC. This happened to me at my first stop after leaving Nappanee as I did a Harvest Host stop to test boondocking with the new setup and I was at 97% SOC. With a significant battery bank it's really a non issue as well as being able to go down to around 20% SOC on LiFePO4's. I did ask about it, if you want you can put in a manual control and manage it yourself but I am staying with the Li-BIM.

It's also neat to see how everything is centrally managed such as the BMS and/or Cerbo GX (not sure which) actually turns off the Solar charge controller which its not needed so you don't have unnecessary current coming in to the battery bank. The solar charger shows "externally controlled" in the setup as it's being managed by the inverter/chargers, etc.

As mentioned above my first stop was a boondocking stop at a Harvest Hosts to put this system to the test. So much so that I even decided to run the slides out on battery power where we typically are told to use the GEN to ensure sufficient power. I was surprised to see only about 5A needed for the slide motors. Then the next morning I decided to also bring in the slides on battery and due to the uphill nature of the coach position on the full wall slide it was significantly more power draw but it did fine. I'm still on the fence as to use the GEN or not but I wanted to trust in the battery horsepower and put it all to the test.

One final item of note. If LiFePO4's have an issue such as a thermal runaway they are going to smoke heavily. An item I think is critical is a smoke detector and I use the Google Nest smoke detectors in my coach which are Internet connected so I will get an alert on my phone wherever I am. All of the detectors in the coach will also announce the problem as I experienced once before when my OASIS heater had an electrical short. While I highly recommend changing your detectors in your coach to these, if you get LiFePO4's I suggest considering something like this strongly.

Amazon product ASIN B00XV1RCRY

I think that about covers it. Here is a brief list of materials from the final invoice:

- 2 x Victron Multiplus 12v 3000w Inverter/Charger with Power Assist

- Victron Cerbo GX

- Victron Smart Battery Protect

- Victron Energy Interface MK3-USB

- Victron GX Touch 50

- VE direct cables

- Custom wiring for proper loads such as for running A/C's on battery without time limits

- 48" 4/0 battery cables

- Li-BIM

- Auto Gen Start module

- HDMI extension cable (for GX Touch 50)

- USB cable for GX Touch 50

- Victron Lynx Smart BMS

- 4 x Victron Lynx smart distributors

- 4 x Victron 12v 330ah Smart Lithium Batteries

- Fuses (150, 225, 300)

- RuuviTag sensor (temp sensor for battery bay)

- Extra parts for backup (fuses, MK3, etc.)

- Manual bypass switch and box to bypass inverters

- Breakers and cutoff switches

- New cables to breaker box from transfer switch via power switch box

- Miscellaneous parts not listed

Final bill: $27K

I will do my best to answer questions but hopefully I can get SES to come partake in the forums here and help educate all on this amazing capability. For those going to Nappanee, Elkhart, etc. I highly recommend considering SES for your battery investment. If ordering a new coach, consider minimizing what you get from the factory and put the money into the experts that can set you up right.

I'd like to thank Winnebago and Newmar for raising your prices so heinously that made this job an easy decision. A new coach is not in the decision matrix at current prices so the nuclear battleship "Ventessex" is for life.

EDIT: I did a google search on solar battery tax credit:

Do Batteries Qualify for the Solar Tax Credit in the Inflation Reduction Act?

Do batteries qualify for solar tax credit? This article explains how the Inflation Reduction Act expands the tax credit for battery storage.

and also this:

When Does the Solar Battery Tax Credit End?

The 30% federal tax credit for battery storage is available for solar battery systems that are installed between 2023 and 2032. At the end of 2032, the solar tax credit will be reduced annually and eventually phased out.

Installing solar plus storage sooner rather than later can secure tax credit savings and a faster solar payback period!

- 2023-2032: 30% solar battery tax credit

- 2033: 26% solar battery tax credit

- 2034: 22% solar battery tax credit

Last edited: