TJ&LadyDi

RVF "Dinosaur"

Yes, it does. Much like trying to get 8-point crimps right on 20-ga hulls without buckling the tube.@TJ&LadyDi does this almost sound eerily like reloading? I am staying away.

TJ

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Yes, it does. Much like trying to get 8-point crimps right on 20-ga hulls without buckling the tube.@TJ&LadyDi does this almost sound eerily like reloading? I am staying away.

Sorry to hear...hope everything is okay. Probably no pickleball for awhile?Just had knee surgery yesterday so no rush.

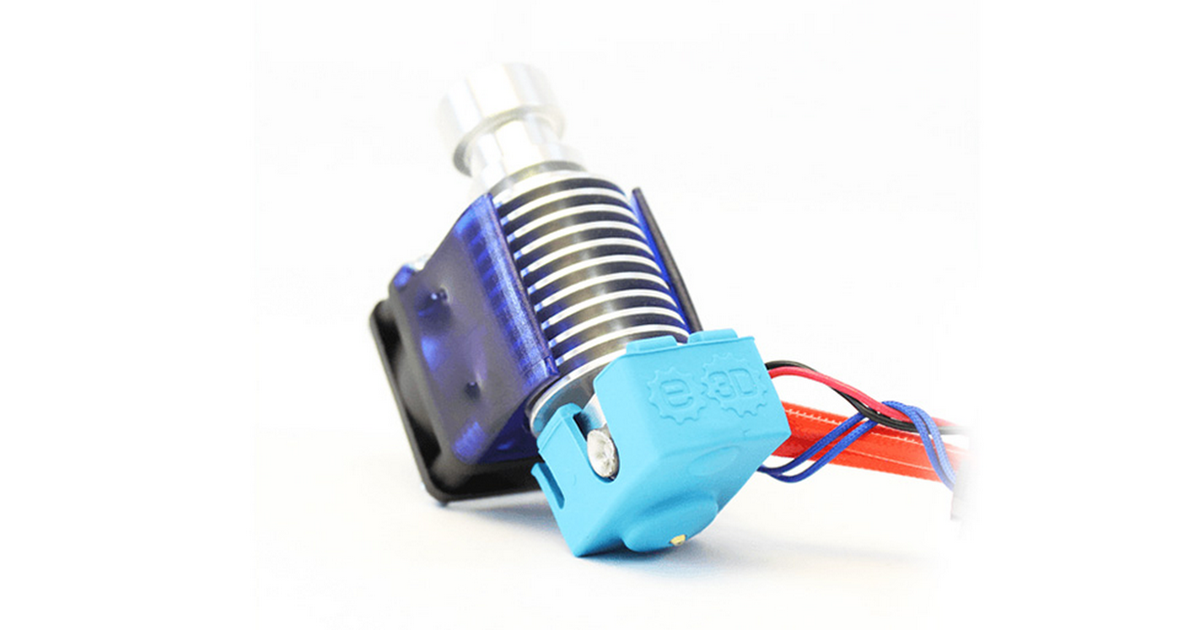

Good instructions for re-assembly of hotend:

Slightly different than the Prusa hotend, but through step 20 seems about the same (different collet)

How To: Successfully Assemble an E3D v6 All-Metal HotEnd | MatterHackers

This detailed guide by the Pros at MatterHackers walks you through the steps to correctly assemble the industry's leading hotend.www.matterhackers.com